James Tuschner has spent 30+ years inside the Tire Enterprise, and 10+ years inside the Monitor Enterprise, centered on the Agricultural & Specialty Markets. His experience consists of time spent at Alliance Tire Americas Inc. (first as Promoting and advertising and marketing Director, then as Director of Enterprise Enchancment) and Denman Tire Corp. He started AG Tire Converse in 2016 www.agtiretalk.com and AG Monitor Converse in 2020. www.agtracktalk.com. Ag Tire Converse is a weblog the place James Tuschner asks tire producers and completely different enterprise specialists for his or her opinions and advice on key topics on this planet of ag tracks. This model focuses on tire lifespan and longevity.

AG Tire Life Span & Extension

What is the widespread life span of a Huge AG Drive Tire (years of service), what steps can producer take to pro-long, and what explicit attributes must purchaser seek for when deciding on a tire to maximise longevity?

Ag Tire Converse Key Takeaways

MAXAM: “As a Regular Effectivity Rule, MFWD & 4WD Tractors (+100 HP) are 65% of the Market – What sells instantly as a model new OE fitment replaces @ 5 years”

MICHELIN: “How will we handle tires, in order that they’ve a better probability to attain their rubber lifespan? Maintain an in depth eye on air pressures, take weight off tires in intervals of prolonged storage….”

ASCENSO: “The standard Rear Ag Tire Place instantly, on Tractors, could be the best to get good effectivity out of- lots fully completely different than functions for Sprayers, Combines…”

YOKOHAMA TWS: “Analysis have confirmed {{that a}} tire’s lifespan will most likely be decreased by 25% within the occasion you drive incessantly on the freeway with under inflated tires.”

YOKOHAMA OFF-HIGHWAY TIRES AMERICA: “Essential contemplate extending the lifetime of most farm tires is minimizing the buildup of heat.”

BKT: “On MFWD Tractors, the Fronts are Drive Tires, sporting out about 2-1 as compared with the rears, significantly the place touring on the freeway is required- they flip 1.3 to 1.5 cases faster than the rears.”

Maxam Tire Worldwide

Greg W. Gilland: Vice President Worldwide Agriculture

Inside the agricultural enterprise, it is how the gear is utilized or the inherent operational requirements which will impact tire life. As agricultural tires are considered “off-road” and by no means US Division of Transportation (DOT) regulated, there are usually not any company pointers to seek out out when an ag tire have to be modified. However, how the tires are utilized will determine the usable service lifetime of a tire. In all circumstances, the sort of tools, soil conditions, utility (depth of use), and air stress repairs might have a direct have an effect on on its capability to ship an improved service life. Listed inside the underneath desk are some widespread effectivity pointers of the Ag enterprise, detailing anticipated tire life span or different cycles by platform or machine class:

Regular Effectivity Pointers inside the Ag Market for Huge Ag Drive Tire Substitute:

- MFWD & 4WD Tractors (+100 HP) are 65% of the Market – What sells instantly as a model new OE fitment replaces @ 5 years.

- Combine / Harvesters are 10% of the Market – What sells instantly as a model new OE fitment replaces @ 10 years.

- Software program Gear is 15% of the Market – Tires are modified every 1-2 years counting on the amount of roading.

All the above service life expectations are predicated on how the tires are mounted, used, and maintained. Listed underneath are some widespread causes for tire elimination or different in all circumstances, MAXAM recommends utilizing ag tires for the longest attainable time irrespective of the sort of tire so long as the tire could also be safely employed to fulfill operational requirements and ship the price of the tires:

Regular Tire Substitute Pointers for Farmers & Growers:

The principle purpose for tire different is excessive tire placed on or tire wear-out, resulting in a scarcity of traction well-known by elevated tools slip costs. How a tire “wears” is straight linked to the exact weight being carried by each axle as dictated by the working tempo of the tools in service. If the tire’s chilly inflation stress is about to the very best air stress based totally on the axle load for a given work tempo, all radial Ag tires (customary, IF or VF) are designed to deflect or bulge on the sidewall transmitting the optimum tire tread footprint to achieve a cheap service life.

In all circumstances, tire producers ought to abide by enterprise necessities that reference or set the helpful air stress based totally on tempo and weight bearing performance. If a farmer or grower chooses to lower the tire air stress to increase the dimensions of the tire footprint with the aim to achieve lower soil compaction or to attain further traction, then the axle load being carried ought to be measured/weighed so that the suitable air stress is acknowledged to verify optimum tire placed on. One different improvement inside the Ag enterprise to spice up every tire placed on and restore life is the addition of metallic belts under the tread, enhancing every the stableness or traction of the tread face whereas rising the resistance to wreck attributable to spin cuts, stubble hurt, or rock impacts. The final word consideration in getting improved effectivity or bigger service life out of your radial Ag tires is to utilize R-1W (W for Moist traction) type tires which may be manufactured with +20% deeper tread than customary R-1 tires providing every elevated resistance to wreck and longer lasting tread rubber.

The arrival of IF or VF Experience in radial tires has allowed numerous the above pointers to be re- written as farmers or growers can each significantly lower air stress with out compromising the carrying functionality of the tire or rising the burden carried with the similar tire footprint (similar gross flat plate). Every utilized sciences allow farmers to achieve increased yields or bigger productiveness inside the topic with heavier or faster tools. Moreover, one different instrument that could be very well-liked inside the European market and rising inside the North American market is the utilization of “On-Board” Tire Inflation or Central Inflation Strategies that ship the aptitude to inflate or deflate the tires as needed based totally on the required work tempo or axle load. It actually works by receiving data from each an RFID or sensor tag, positioned by wheel place on the tools, and allowing the operator to manage the tire inflation stress in precise time with out having to stop the tools guaranteeing enhanced tire service life.

In all circumstances, whether or not or not working inside the topic at gradual speeds or transporting the tools (roading) from topic to topic at elevated speeds, managing right tire inflation pressures for every work utility will ensure that the tires can ship the optimum effectivity and prolonged service life by:

- Lowering ground compaction as tire load relies on the exact load per axle or per tire as needed.

- Bigger crop yields as a result of the compaction have an effect on on the soil is minimized by the improved tire footprint.

- Improved gasoline effectivity as a result of the tire is optimized for each work utility or towed implement.

- Bigger productiveness inside the topic as a result of the tire’s footprint and traction current elevated effectivity.

Michelin Ag

David Graden: Operational Market Supervisor – Agriculture

This question has stricken farmers and RV goers, alike, for a extremely very very long time. As a tire nerd, what I uncover attention-grabbing is the definition of “Tire Life Span” will most likely be fully completely different for each tire producer on account of variations in prime quality, meant utilization, mileage/hours use, and plenty of others. I desire to stipulate tire life as a result of the lifetime of the rubber that tire is constructed from, which I will make clear barely further later.

At Michelin, what we’ve found by way of a few years of research and enchancment is, tires cannot be developed for the easiest of all worlds. Some tires should be decrease and chip resistant, which suggests the rubber compounding ought to be extra sturdy (briefly). If you would like a tire that is good on laborious surfaces and snow, the rubber compounds should be further supple and have further flexibility. At current, it’s not attainable to individually maximize each of these in a single tire, so we (Michelin) work very laborious to get basically probably the most out of each and blend them for explicit utility tires like “Extreme Traction” and “Laborious Flooring” specs.

My stage is rubber compounds lastly determine how a tire will age. Extra sturdy rubber compounds will age in one other approach as compared with softer rubber compounds. Then, in any case, you even have to consider exact utilization and the atmosphere the tires will dwell in.

Twenty years prior to now, tires aged very in one other approach than instantly. Sooner than about 2006, tires would harden over time. In reality, many farmers and tire sellers would purchase farm tires and permit them to take a seat inside the photo voltaic for months and even years to permit them to proceed to “treatment.” The thought was the tire rubber would proceed to harden and could possibly be a better product for the tip particular person by the purpose they’d been provided. Whereas there is also barely truth to this concept, the final idea really didn’t impact the effectivity of the rubber.

Once more then, this impression was attributable to aromatic oils, which had been used inside the making of tires. Reverse to the establish, aromatic oils did not give tires their stunning odor. In reality, they’d been used inside the processing of rubber compounds and added that “sticky” impression to rubber on laborious surfaces in moist conditions, together with improved placed on and sturdiness. Sadly, spherical 2005, the ETRMA (European Tyre & Rubber Producers’ Affiliation) determined these oils contained carcinogenic properties and labored to ban them from all tires which may be manufactured in and imported to EU nations by spherical 2010. Successfully, this posed an enormous downside for all principal tire producers on account of now they wanted to find another choice to those oils. As of instantly, testing continues with oils resembling safflower oil, soybean oil, sunflower oil, and plenty of others.

Sooner than the elimination of aromatic oils, we wouldn’t see this cracking for as a lot as 20 years, counting on environmental conditions, in any case. At current, on account of Michelin’s design and actually deep customary depth of our lugs, we generally see about 14 years sooner than the rubber begins to level out cracking inside the sidewall, aka ozone cracking.

To get to the aim, whereas working spherical tires of all producers, beforehand, I’ve personally witnessed a median of some 14-year rubber life for elevated end tires and as little as 8-10 years for very low- worth tires. For Michelin, though, the effectivity stays by way of the tip of the lifetime of that rubber due to the design and depth of our tread bars. On the end of rubber life, the Michelin tire will normally proceed to have necessary lug depth for tractive functionality and perform very successfully. In reality, from a tread placed on perspective, all Michelin tires have some resistance to stubble, so many tires really dwell to that 14-year rubber lifespan as a substitute of being ruined by stubble hurt. After that, I are more likely to advocate together with Michelin tubes to the tire to further lengthen the life and even steer clear of inconvenient downtime in the midst of the season.

The next question is how will we handle these tires, in order that they’ve a better probability to attain this rubber lifespan? Successfully, rubber is negatively affected by heat, excessive or continued work under torque, storage practices, and plenty of others. For those who want to take steps to elongate the lifetime of your tires and get the entire life the rubber compounds have to produce, I prefer to advocate the subsequent:

- Maintain an in depth eye on air pressures. Try and not let the air stress fall too low over the winter months.

- If attainable, take the burden off your tires by lifting the machine barely all through prolonged durations of storage. It is going to help to cease stress on the excessive of the tire casing and set off “flat recognizing.”

- When the machine is simply not in use, retailer in a cool dry place. Heat is the enemy of rubber and might set off it to fatigue lots faster.

- Be sure your tires keep clear and free from any petroleum based totally merchandise. I’ve seen many tires the place oil has puddled under or on excessive of tires for an prolonged time interval. This causes rubber to become brittle and crack.

- All through operational months, pay shut consideration to your tire pressures. Be sure to have them set on the proper helpful pressures for the load, tempo and utility. It is going to cease pointless damages and placed on on the lugs and casing of a tire. You presumably can contact your native licensed Michelin Ag provider for this information or your native Michelin product sales marketing consultant, as these options generally should be calculated based totally upon your machine weight, stability between entrance and rear and utility.

To conclude, I firmly think about you get what you pay for in relation to tires. Very like your pickup truck or family car, within the occasion you keep them, they will ultimate for a extremely very very long time.

Ascenso Tires North America

Nick Phillippi: Product Supervisor / Technical Assist North America

Wow, one different highly effective question with so many questions needing answered to supply an awesome reply. What is the tractor used for? Roading, heavy plenty, heavy torque? What variety of hours is it used per yr? 100, 300, 600? What conditions are the tires subject to? Manure, on a regular basis in photo voltaic, gasoline or oils, extreme heat or chilly?

Rear ag tires, using the 80% rule, must ultimate 8 years with no factors in common conditions. Applicable PSI for weight and tempo, common torque, ~20% roading, saved under cowl when not used for longer durations. I base that on the reality that almost all warranties instantly are 7-10 years and anyone is conscious of the statistics to set these time traces. I’ve seen tires ultimate 20 years and some that didn’t make it 4 and I’m optimistic your entire listeners have as successfully. A number of of this unfold is due to the prime quality of the product little doubt and some is due to the care of the product.

My opinion is that the standard Rear Ag Tire Place instantly, the subject of this question, on tractors could be the best to get good effectivity out of. Lots fully completely different than functions for sprayers, MFWD, combines, carts and even numerous the biggest implements. They’re sized to have the flexibility to fulfill the burden and tempo desires with out being stretched to their limit in most set ups from the manufacturing facility and they also don’t have lots stubble hazard. We do nonetheless need on board air to maximise the tire effectivity, significantly with VF merchandise.

With further science involved, the compounding has become very technical and important. Utilizing chemical substances and completely different substances, accomplished appropriately, has helped inside the areas of ozone cracking, stubble hurt, placed on and adaptableness for each sort of functions. The proper use of these substances gives worth to a tire and may’t really be seen or appreciated by assertion.

Growth may be mandatory, from a dimension of life perspective, the usual inside liner on tubeless tires is a key measure of top of the range. If a tire sits and would not lose further air than is common with local weather changes its indicative of a top quality inside liner and most undoubtedly a top quality tire. As for air stress, I think about when storing a tire for an prolonged interval, it have to be set at merely over the air stress for the burden being held. I am really old school with this, nonetheless I moreover suppose if weight cannot be taken off a tire, then I might try and switch the tractor (car) barely every 2-3 months when in storage for the winter. Some will say its’ not needed nonetheless I say it can presumably’t hurt.

The truth is good practices will add to the lifetime of a tire. Appropriate inflation is important, even when the auto is sitting. Washing off the tires from manure, oils or completely different worldwide substances is an efficient apply. Storing tires out of direct daylight when attainable could even really repay in tire life over time.

Yokohama Off-Freeway Tires America, Inc.

James Crouch: Nationwide Part Supervisor—Agriculture and Forestry

There is a monumental differ of variables influencing the lifespan of a farm tire, from the event and prime quality of the tire to the way in which it’s used, native soils and conditions, and even how a specific operator drives and turns. Nonetheless farmers can pull a few levers which will help them get basically probably the most life out of their tires.

The first technique to maximise tire life is to buy high-quality tires. Radials are more likely to final greater than bias- ply tires. Pay attention to the provides used of their improvement—as an illustration, all-steel improvement is best for durability and heat dissipation, whereas casings made out of polyester plies will keep their kind and placed on increased than nylon. Stubble guard compounds cut back punctures and stubble hurt. And explicit design choices ranging from bolstered sidewalls to bead guards can improve tire life, too.

Tread pattern has an infinite have an effect on on tire life, and by no means on a regular basis one of the simplest ways people suppose. For instance, deeper lugs are normally not on a regular basis increased in relation to deciding on amongst R-1, R-1W and R-2 tires on account of tire life will not be solely a matter of how lots rubber you have gotten. In case you’re working primarily in mud, the deeper lugs of the R-1W or R-2 is normally a pleasant funding. Nonetheless within the occasion you’re working primarily in dry or laborious soils or doing a great deal of roading, deep lugs will scour off further quickly or flex and crack, really lowering your tire’s life. In these circumstances, you’d be increased off with a shallower R-1 tread.

Otherwise you would get away from the standard curved R-1 lug altogether. For tractors doing a great deal of roading, a denser, hybrid block tread identical to the Alliance 550 or Alliance 363 can reduce abrasion placed on and dramatically enhance tire life—and likewise you’ll have a better expertise, too, which could really enhance the lifetime of your tractor.

Speaking of rubber, storing tires out of the photo voltaic, rain and winter local weather can improve tire life—UV, water and extreme temperatures take their toll on rubber compounds. So can oil and completely different solvents. Moreover, keep tires away from electrical motors, which produce ozone that damages tire compounds and accelerates tire getting older.

Essential contemplate extending the lifetime of most farm tires is minimizing the buildup of heat. As thought of one in all our engineers used to say, “A tire is born in heat, and it dies in heat.” Don’t overload your tires. Don’t perform at speeds elevated than they’re constructed to cope with. And the one neatest factor you’ll be able to do in your tires is to perform them on the suitable inflation stress, which minimizes the opportunity of overheating.

Remaining—nonetheless fully not least—is working your tires on the proper inflation stress. Sustaining the suitable inflation stress optimizes the tire’s footprint. The upper the footprint, the lower the slip, the lower the heat, and the longer the tire life. It’s that simple.

That’s why, within the occasion you may afford it, a central tire inflation system (CTIS) is normally a pleasant funding, significantly you most likely have moreover invested in IF or VF tires, which ship monumental benefits from very low inflation stress inside the topic. And within the occasion you’re inflating your tires manually, just a few minutes and a $5 stress gauge can add months or years to the lifetime of your farm tires.

Yokohama TWS

Chris Neidert: AG Promoting and advertising and marketing, Teaching & Enchancment Supervisor for Trelleborg & Mitas Tires – North America

Sadly, attempting to predict the standard life span of an AG tire is like attempting to pick out the easiest automobile. There are a great deal of variables, and it relies upon upon the making use of, environment, and others.

We’ll technique this question as a result of the above assertion reads – what steps can a producer take to pro-long tire life.

ADJUST AIR PRESSURE MORE OFTEN

There isn’t a such factor as a typical stress at which you’ll be able to do the whole thing. Form of ground, tempo and the sort of load all contribute to creating an air stress dedication.

Overinflation

Many farmers generally tend to increase the inflation stress of their tires as a precaution, to steer clear of having to look at tire stress based totally on load with a function to save lots of time.

Overinflation may end up in premature placed on in positive conditions. Nearly speaking, an overinflated tire is further rigid, which is further applicable for the freeway. However, inside the topic, it ought to have a decreased contact patch with the underside. It is going to reduce its traction performance, enhance slippage, and enhance ground stress leading to soil compaction. In the long term, this will considerably reduce the manufacturing functionality. There is a principal hazard of speedy placed on with extreme inflation stress. The extreme stress all through the tire corresponds to the stress exerted on the underside, the higher the stress, the additional the tire sinks into the unfastened soil inside the topic, significantly in moist conditions. Deep tilling will lead to excessive slippage and finish in speedy placed on to the tread. On the freeway, an overinflated tire will bulge inside the heart, lowering contact with the underside inside the coronary heart of the tread, which is susceptible to lead to faster, further marked placed on on the central part of the tire. Our occasion to the very best is displaying overinflated placed on. Uncover how the tread is worn inside the coronary heart.

Beneath Inflation

There are fully completely different drawbacks to driving with under inflated tires (we do not advocate this under any circumstances), leading to excessive placed on.

What sorts of placed on are linked to an underinflated tire:

When driving, an under inflated tire tends to flatten out proper right into a attribute variety. Excessive casing deflection occurs on the stage of the sidewalls and the tire can’t regain its genuine kind. This ends in a rise in interior temperature, the development of the tire deteriorates progressively and irreversibly, which can lead to a sudden puncture or break inside the casing. Although the harm would not appear immediately, it’d become seen later, even after the inflation stress has been adjusted.

Analysis have confirmed {{that a}} tire’s lifespan will most likely be decreased by 25% within the occasion you drive incessantly on the freeway with under inflated tires, significantly if such a ground is extraordinarily abrasive. The tire efficiently overheats, making the rubber further supple and subsequently further weak to placed on. Ideally, you will need to modify inflation stress based totally on the load, the making use of, and the sort of ground.

Precisely Ballast The Tractor

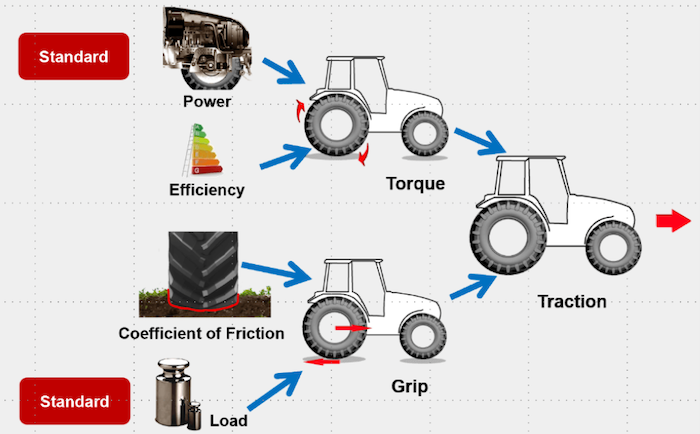

Along with air stress, tractor ballasting is one different neglected area of tractor operation. You spend some big money to get that power from the tractor, and also you may wish to maximize that change of power to the underside. Our picture depicts what you could be lastly attempting to carry out. Get basically probably the most out of your tractor horsepower. Listed below are some suggestions that can enable you to calculate the optimum ballast or full tractor weight.

MFWD Purpose is approx. 120 lbs./Tractor hp.

When you may have a MFWD (Mechanical Entrance Wheel Drive) tractor, take the horsepower and multiply it by 120. That’s your aim full tractor weight. This could possibly be for heavy pulling.

4WD Purpose is approx. 105 lbs./Tractor hp.

When you may have a 4WD (4 Wheel Drive) tractor, take the horsepower and multiply it by 105. That’s your aim full tractor weight. This could possibly be for heavy pulling.

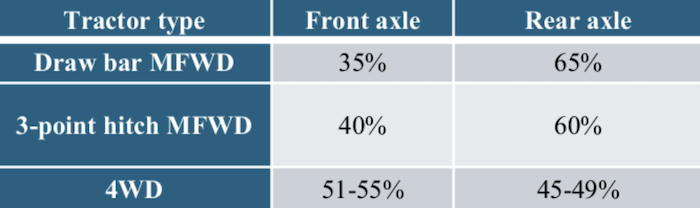

Subsequent that you must make certain that the whole tractor weight is appropriately distributed between the doorway and rear axles.

Here is a chart suggesting axle weight splits to accurately unfold out that full tractor weight for optimum tractor effectivity and tire effectivity.

The surest technique to substantiate your weight and axle splits is to have your tractor weighed on scales.

For further information on making exact calculations, please contact me.

Buy the Correct Tractor Tire

If the air stress that you just may wish to be using is on the upper end of the tire’s load desk, take into consideration switching to IF or VF tires. IF (Improved Flexion) tires will let you run as a lot as 20% a lot much less air and nonetheless carry the load of a traditional tire. VF (Very Extreme Flexion) tires will let you run as a lot as 40% a lot much less air and nonetheless carry the load of a traditional tire. This lower stress will current benefits. The tire will run cooler and provide longer tire life. An even bigger footprint will put further rubber on the underside inside the topic and lengthen tire life, reduce compaction, and provide increased traction.

Buy the Correct Combine Tire

Just because the above, in case your combine tire air stress is on the upper end of the tire’s load desk, take into consideration switching to CFO or CHO tires. IF or VF CFO (Cyclical Space Operation) tires can stand as much as a quick overload state of affairs of between 33% and 50% from the nominal load functionality. CHO (Cyclical Harvesting Operations) tires can current as a lot as an 80% load bonus from the nominal load functionality. These two bonuses will go an prolonged technique to extending your combine tire’s life all through its cyclical operations.

Choose the Correct Tire Dimension

It is important, when searching for tires, to determine on the very best tire dimension for the actual piece of equipment. To steer clear of premature placed on and guarantee your tire’s resistance, make certain that your tire dimension and cargo index correspond to your most plenty along with implements and trailers. In any case, do not overload your tires and adjust to the tire’s load desk for helpful air stress, on a regular basis consulting collectively along with your Licensed AG Tire Vendor.

Choose Tire In step with Software program

The tire’s utility is no doubt one of many numerous parts which can outcome within the premature placed on of your agricultural tires. When you may have chosen low-pressure tires designed for work inside the fields and you use them in a quarry or forest area, this will considerably pace up the pace of injury together with the hazard of even bigger points. In case your utility is mostly mowing, inside the yard or engaged on improved roads, a a lot much less aggressive tread pattern will current longer tire life than an R-1 or R-1W tread pattern.

Rotate Your Tires

When your correct tires placed on faster than your left tires, or the alternative strategy spherical, you presumably can swap them over, on the scenario that this is not attributable to a mechanical downside (misalignment or mounting error). Swapping your tires spherical is also an attention-grabbing technique to optimize placed on over an prolonged time interval. That’s notably useful for the doorway tires of a sprayer or a carefully roaded tractor.

Confirm Mechanical Scenario

In all probability probably the most frequent causes of ag tire placed on is geometry points. This type of downside is linked to the a number of kinds of strain imposed in your tires all through use.

The angle settings to be checked are:

- Between the 4 Tires & Freeway

- Between the Tires & Tractor

- Incorrect Adjustment between the Tires themselves.

Confirm the parallelism:

The angle between the trail of journey and the axis of the wheel is named parallelism. You want your tires to be fully parallel to the trail of journey. If this is not the setup, you’d placed on the within (toe-out) or the skin (toe-in) of the tire. Some toe out angle is useful, with a function to offset the mechanical power linked to the traction strain encountered by the doorway axle when in four-wheel drive.

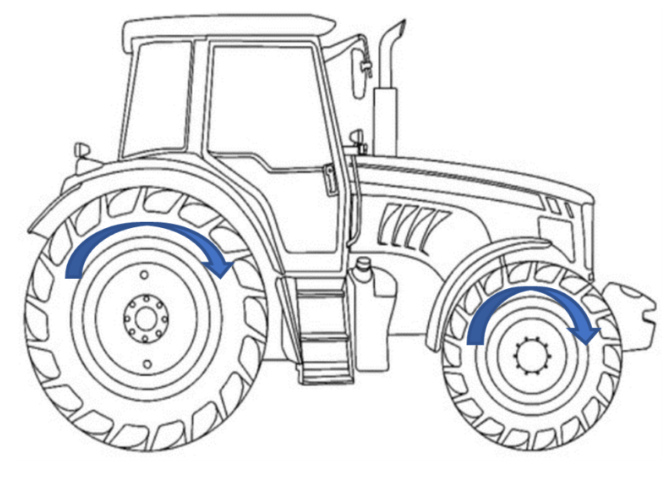

Make Sure Lead/Lag Ratio is Applicable

The lead ratio is the number of rotations the smaller entrance tires make in relation to the larger rear tires on MFWD tractors. It permits the synchronization of the doorway and rear axles of the tractor. All MFWD tractors might have some constructive lead. This suggests the doorway tires flip barely faster than the rear. It ought to be proper to steer clear of your tires sporting rapidly, supplied that an incorrect lead ratio ends in premature placed on to the two entrance tires as compared with the rear tires or the alternative strategy spherical.

The inaccurate lead ratio moreover ends in placed on to the mechanical parts. To take care of your tires longer, make certain that your ratio is inside tolerance. Common lead ratio is 1-4%. If the lead ratio is above 4 or 5%, the rear axle slows down the doorway axle, which signifies that the doorway tires are actually pulling the tractor, thus inflicting placed on to the doorway tires. If the lead ratio is 0% or underneath (lag), the rear axle pushes the doorway axle an extreme quantity of, inflicting further slippage on the rear and making the doorway axle a lot much less atmosphere pleasant. In case you keep driving in these conditions, together with tire placed on, you could be susceptible to hurt your tractor’s gear area. You presumably can contact me for help on this.

BKT USA, Inc.

Dave Paulk: Supervisor Space Technical Corporations

The life span of an Ag tire depends on the way it’s used and for what features. If an ag tire is used solely inside the topic, they will ultimate for for much longer sooner than they placed on out. Sadly, with farms scattered, and tractors touring on the freeway, the lifetime of ag tires is diminished because of the freeway placed on.

On MFWD tractors, the fronts are drive tires, nonetheless placed on out about 2-1 to the rears, significantly the place touring on the freeway is required. The reason is that the fronts usually flip 1.3 to 1.5 cases faster than the rears. The crown of the freeway moreover performs a component in how the tires placed on. The most effective entrance tire will normally placed on out faster than the left entrance. The most effective rear will exhibit indicators of freeway placed on nonetheless are larger and don’t flip as many cases as a result of the fronts. The freeway placed on doesn’t current up as quickly. Rotating the fronts from correct to left will lengthen the life for a while longer.

Appropriate air pressures for the making use of, weight, and tempo are essential to caring to your tires. Underinflated and overloaded tires will fail prematurely and worth money to alternate. Air pressures used for topic work versus air pressures needed for transporting on the freeway are fully completely different. The faster that gear runs, the a lot much less load carrying functionality a tire has. When ran underinflated at freeway speeds, heat generated by the tire is simply not dissipated as quickly and may set off tire failure (ply gap separations, sidewall separations, and bead hurt).

Using the suitable helpful wheels is important in numerous strategies. Sometimes, there is a helpful wheel with alternates. The helpful wheel will give the tire a better footprint on the soil and on the freeway. The place compaction is important, the tire is unfold out over an even bigger area (longer and wider). Actually useful alternate wheels will work with out damaging the tire, nonetheless usually don’t give the optimum footprint. If wheels are too slim, it pulls the sidewalls of the tires in and locations further stress within the midst of the tire tread. If wheels are too intensive, the beads are pushed out and creates undue stress inside the bead area and reduce sidewall. VF tires play prominently into this as they’re typically run at lower air pressures and gives a wider and longer footprint with the suitable wheels.

A problem that plagues farm tires is stubble hurt. GMO crops are lots stronger and extra sturdy than what was planted sooner than. Cotton, soybeans, corn, and sunflowers are a few of the GMO crops in use instantly. The stalks are much more sturdy than rubber and may go straight by way of an ag tire when pushed on or all through the stalks. There are a variety of strategies to battle stubble hurt factors. Stalks could also be decrease barely taller and by no means correct on the ground. This allows the doorway tires on the combo and the tractor to push them over as a substitute of sticking into the tire. Stubble guards or stubble stompers may be utilized to push the stalks over sooner than working over them with the tire. Instead of working straight over the stalks with the tractor tires, straddle the rows, if attainable, to steer clear of hurt to the tires. Although some producers have stubble hurt warranties, a farmer nonetheless ought to pay for the labor and most warranties for stubble hurt are normally not free replacements. It could be pretty pricey to alternate tires for that purpose when it is pointless.

Compounding of the rubber for the tread is important for stubble hurt and compounding for tread and sidewalls for ozone security. Ozone is a killer for rubber merchandise. Most tires have some form of ozone security inbuilt, and might want to have this security to have a conventional life span. With out ozone, if a tire is used just some weeks a yr and sits out inside the photo voltaic, it ought to start cracking in a few years.

Utilizing metallic belts in ag tires can serve a twin goal. Tires could also be made with a metallic belt inside the tread area or made with an all-steel casing. A metallic belt strengthens the casing and gives a measure of resistance to punctures inside the tread area. It doesn’t make tires bullet proof, nonetheless the metallic belt does help. As well as they help the integrity and sort of the casing preserve intact. Some tires are made with all metallic casings. These tires have metallic working from bead to bead in a radial design. This helps to cut back hurt to the sidewalls and tread area of the tire.

Tires must be taken care of when saved inside the winter or downtime to keep away from losing time and money. Sooner than storing for an prolonged time interval, resembling over the winter, there are a variety of points that could be accomplished to cut back points inside the spring. Air the tires as a lot as near most air stress sooner than storing. Resulting from ambient air temperatures, air pressures will go up and down. Within the occasion that they happen to go flat, the rim can decrease into and hurt the tire. Retailer out of the daylight if attainable. The ozone inside the air can hurt the tires and set off them to crack prematurely. Retailer tires away from fossil fuel- based totally liquids. These are harmful to rubber merchandise and may set off the rubber to deteriorate over time. It’s normally intelligent to scrub the filth, mud, sticks and rocks from the wheels. Barely little little bit of prevention saves money down the freeway.